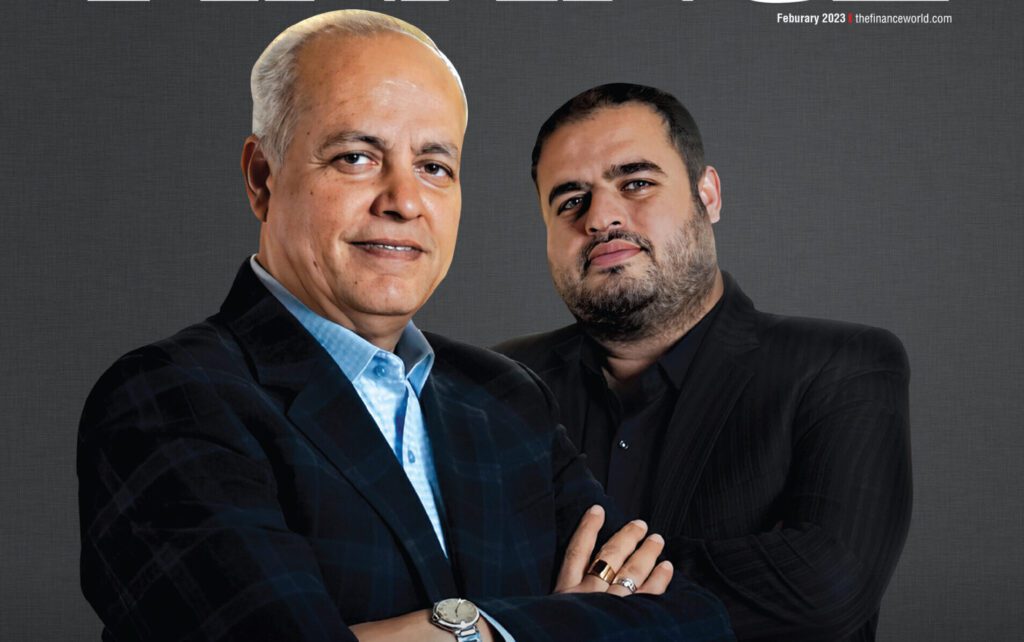

Rajender Jhawar, a seasoned trader of used oil since 1993, founded Vision Recycling & Reprocessing Industry FZC in the Fujairah Freezone. In 2008, Mukund Jhawar, Rajender’s son and current CEO, established a company with the aim of collecting used engine oil in the Emirate of Fujairah. This company underwent a major transformation, which included partnerships with 1 Local and 5 Expats from the same family, resulting in the formation of the current Vision Recycling & Reprocessing Industry LLC.

Exclusive to The Finance World Magazine

Q. Can you share your experiences during the early stages of setting up your business in the UAE?

Rajender Jhawar: I came to the UAE in 1993 and started trading activities with 20-25 products of various lines, such as children readymade garments, auto parts, G.I. Pipes and then fresh flowers and fresh vegetables. Gradually, I was always doing oil exports from this country to India because there was a lot of used oil available here. In 1997, The Basel Convention Act came into effect, which led to the banning of oil exports. Thus, there was a lot of used oil in this country, so I planned to start up an industry here. I had a background about industries because when I was in India, my maternal uncle had various kinds of Industries, and edible oil was one of them. Hence, I got an idea about oil recycling and set up an industry in 2000 in the Fujairah Free Zone. We started with a capacity of around 50 tonnes a day, and this kept going well until 2010. After 2010, we shifted our plant outside the free zone and increased the capacity from 50 tonnes to 200 tonnes per day. That was a time when my son came with me and started looking into the business. Until 2015, we were running the same thing, but after that, my son had new ideas to explore, and he wanted to start the distillation column as well, so we set up the distillation column in the factory, and from there onwards, he was the one who has been mainly looking into the business, and I started to take a back seat. He was the one who continued what we have been doing.

Mukund Jhawar: We have started the distillation column wherein we distil oils and cut them and make them into specialised industrial oils. We have a capacity of doing about 180 tonnes as of today. Additionally, the capacity of 200 tonnes of used oil is always there.

Q. Mukund Jhawar, can you describe your experience when you joined and had to build what was already there for you?

Mukund Jhawar: We were primarily into used engine oil, but the problem with used engine oil is that you can only expand that product to an extent because the collection of used engine oil is a big issue. Additionally, with competitions coming into the market every day, we decided to get into raw material where supply would not be an issue. That was the reason behind our decision to shift to the distillation column where we can distil any type of oil, the raw material will not be an issue, and expansion is endless.

Q. What challenges have you faced in the recycling industry and how did you overcome them?

Rajender Jhawar: In the very beginning when we started with this industry, people used to recycle oil with acid treatments, but in the country being modern, we were not supposed to do that. So, we had to start the clay treatment process, but even in this process there was a lot of solid waste coming out, so we had to keep on making sure that we go with the latest trends

that were happening worldwide. From the clay treatment, we gradually got into the distillation column treatment, and then from there onward, there were further more changes. Today, we are running a plant with zero emissions of waste from the factory, which means that we take the used oil and, except for a little bit of water, there is no other waste left out in the factory. Everything is a sellable product; we sell out each and every product from whatever is there, and we even treat the water and reuse it in our plant for the cooling systems. These are the basic changes that we had to come across because every now and then when a new process was introduced, we had to keep on improvising, but we were very happy about getting the full support and cooperation from the government; they helped us to come out with the best technologies available worldwide.

Mukund Jhawar: There were a lot of changes that actually started happening from 2010-2015 when the industry itself got in a lot of new methods of recycling used oil because many different technologies were not proven yet. So, we had to make sure first that the technology is successful and environment-friendly. That was one of the biggest challenges that we could face. Accepting a new technology and running it successfully was the biggest challenge that we had to face.

Rajender Jhawar: We were able to adopt the latest technologies, and this become of the reasons we are today the oldest plant that is still running sed oil recycling with the latest which is the solvent extraction technology.

Q. How are you passing on your legacy to the next generation of your family?

Rajender Jhawar: I remember when my son was doing his final schooling days, that was the time when I asked him what he would like to do next, and he always showed keen interest in the same industry. So, I started making him work right from the collection centres to other small things to understand how hard it is going to be because for me the journey was not very easy, and I made sure that he could take up all the hardships. With that, he slowly and gradually kept on improving himself, and today he is where he should be. I feel quite proud about my son because he has taken his things very honestly, and he is running a good show. I would love to see that moment where my grandchildren come to see what they would like to do.

Q. How is the next generation preserving the company’s values and supporting its growth?

Mukund Jhawar: My father’s basic principles of business were not to cheat anybody, be always at your word, and always ensure the best quality of the product you supply to the market. These are the three standard principles of my factory; irrespective of how high the demand is or how volatile the market is, we ensure that our commitments are done irrespective of the profits or the losses that we have to make. We always take care of our staff as extensive family members of ours.

Q. What are Vision’s goals for the future, and how do you plan to achieve them?

Mukund Jhawar: As far as the recycling oil is concerned, I would like to start with Lubricants Manufacturing that is where I would want to put my foot forward. In terms of the fractional distillation, we are currently achieving targets of 200 tonnes per day, but I would want the plant to have a capacity of around 400-500 tonnes per day, which is a sizable business in my opinion.

Q. How does Vision keep up with advancements and trends in the recycling industry?

Rajender Jhawar: What we are looking at is hydrogenation, and for that we have already been in touch with our consultants, trying to see what possibilities are there. At present the implementation of Hydrogenation technology is not here in UAE as the economics of this technology does not work, so to run an industry, any technology to be adopted has to be profitable. As of now, the technology which we are running is good enough because it does not emit any waste. The major thing for any recycling industry is not to generate any kind of waste, which is considered to be a big achievement.

Q. What is your advice for those interested in starting a business in the UAE?

Rajender Jhawar: To those genuinely interested in coming, I would like to emphasize that Dubai has provided a home for many and the key to thriving here is hard work and honesty. As long as you don’t conduct any mischievous activities, and run your business with integrity, the government will be cooperative and supportive of your success. Dubai offers the best of both Eastern and Western cultures, making it an unparalleled place to raise children.

Q. What is the key to success in the UAE?

Rajender Jhawar: The key to success is hard work and honesty. If you put in the effort at the start, you won’t regret it. When starting a business in the UAE, you may encounter challenges, but if you continue to work hard, you will be well-rewarded. Additionally, perseverance and determination are also important qualities for success. Don’t give up when faced with difficulties, instead, approach them as opportunities for growth and learning. Embrace challenges and continue to work hard, and you will eventually see the rewards for your efforts. The UAE is a place that values hard work and recognizes those who put in the effort, so keep that in mind as you navigate your journey towards success.

Q. Do you have any final words for our readers, especially those in the recycling industry?

Mukund Jhawar: I personally feel that the UAE itself is a land for opportunities, and it welcomes you with both hands open. When it comes to the recycling industry in particular, there are many products that are still available here which you can start up to recycle. If you have the right knowledge and the right background, you should definitely try your luck here.